Mobile Asphalt Plant

FEED HOPPERS (COLD BINS)

Each bin having independent belt conveying system driven by AC variable speed motors synchronized with load cells for accurate and best weighing of aggregates (to minimize overflow of hot bins) . At the discharge end of gathering conveyor a single deck vibrating screen is provided for removal of oversized aggregates. This arrangement saves fuel and also eliminates the blockage of overhead chutes by oversized aggregates. The Dust bin is supplied with a electric vibrator to allow smooth flow of dust in high humid areas. The bins are supported on sturdy steel structure and loading mouth of 2.76m X 2.20m.

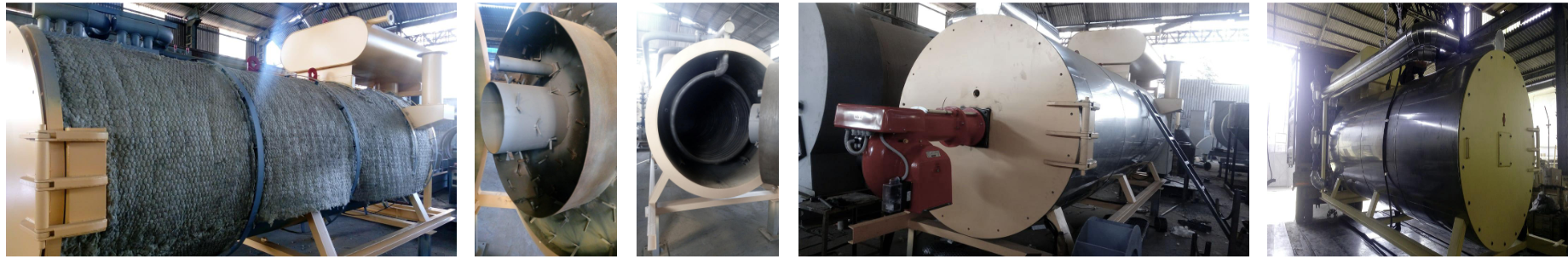

DRYER UNIT (THERMO INSULATED)

The Dryer drum is counter-flow dryer with four-wheel friction drives by shaft. It is fully insulated to prevent heat loss. Modulating type burner with simple operating mechanism maintains perfect air / fuel ratio resulting in perfect combustion of fuel. Consequently, High fuel efficiency and Environmental friendly are achieved.. The burner, giving high energy output with low fuel consumption is positioned in such a way that the flame direction creates a counter flow situation with heat control in all seasons. The proven flight design ensures a perfect distribution of the flow of aggregates. Replaceable internal lifting flights are designed to ensure optimum heat transfer from hot gases to aggregates. A suitable capacity separate service fuel tank is provided for dryer burner

MODULATING BURNER

A First Class Modulating Burner with turbojet proportioning pressure, atomized fully endorsed, capable of burning F.O. I Diesel or L.D.O. Our Burners are equipped with flame failure detectors and sequential auto controlled drums. The blower & exhaust are activated before ignition is on, or flame is produced. Suitable pumps and motors are selected for an efficient flow of fuel. Gas burner is Optional.

BAG HOUSE FILTER UNIT

Fine dust is absorbed by filter bag type air pollution control unit to meet the most stringent emission control levels with pneumatic bag cleaning system, Dust re-feeding to filler pneumatically or by bucket elevator through screw conveyor. It operates in forward-reverse mode Fitted with safety devices for temperature control. Bag house filters are envied in the industry for their guaranteed savings on power, lower maintenance

TWIN LANE HOT BUCKET ELEVATOR

Twin lane chain and toothed sprocket at the drive for the bucket elevator ensure smooth operation of the entire elevator system. Eliminating unbalancing of buckets during heavy loads when the plant is operated at full capacity. Double sprocket chain drive with a four-piece type fully covered box for easy installation on the tower container frame. The hot aggregate bucket elevator is a totally enclosed chain-driven system. Bucket tips are double reinforced for maximum durability. The elevator unit is electrically driven from the head shaft via a chain system. Sytechs bucket elevators are designed for long service life and easy maintenance access. The use of Super-tough wear-resistant materials and a special entry chute design result in superior performance.

FOUR DECK VIBRATING SCREEN

Totally enclosed dust sealed housing, 4nos. discharge chute with removable rails and access for maintenance and mesh replacement. A properly sized motor vibrator to create linear motions which prevent the clogging of the screen by the flow of aggregates. The vibration amplitude of the screen can easily be adjusted by increasing or decreasing the weight of the fly-wheel on each end of the vibratory motor and high sieving efficiency for each type

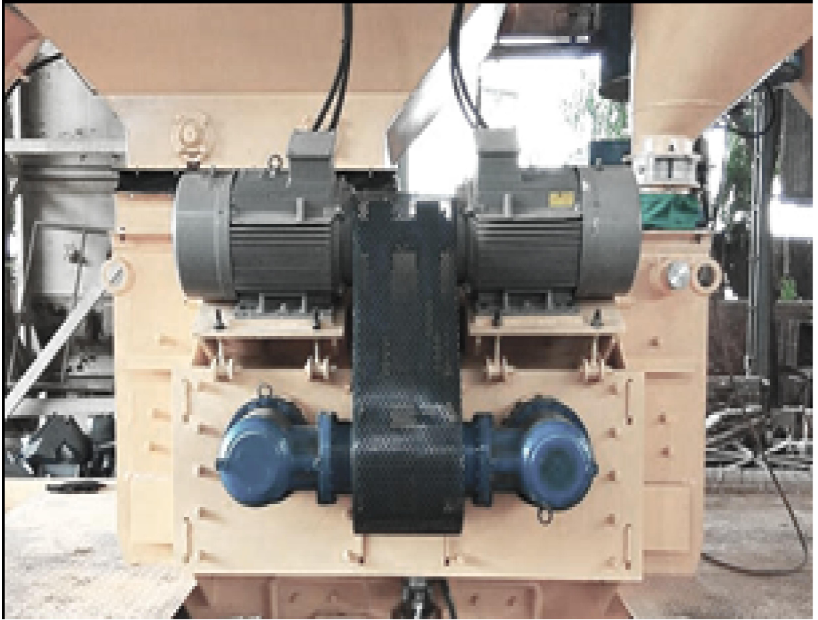

PADDLE MIXER UNIT

The anti aging mixer is a double shaft pugmill type. The adoption of the circulation mixing system results in uniform mixing within a short time even with fine grain composition. Liners and tips of the mixer are made of Ni - Hard material and are of anti-abrasive cast alloy steel, ensuring long life and durability. The HR Steel linear plate (with temper hardening) and tips are easily replaceable. The dumper type discharge gate allows smooth discharge of mixture across the full width of the mixer.

THERMIC OIL HEATER

Thermic oil heater (boiler) of suitable capacity Kcal./Hr provides efficient hot oil circulation with auto temperature control system to maintain precise asphalt temperature. The Hot oil circulates through the asphalt pump, asphalt pipeline, asphalt weighing hopper and mixing unit in suitable flow capacity supplied with service fuel tank for burner.

BITUMEN STORAGE TANKS

Fully insulated Bitumen Storage tanks with efficient heating system through thermic fluid boiler and with jacketed bitumen pump station, insulated jacketed bitumen pipeline supply to bitumen weighing buckets, feeding through auto control valve. The bitumen is automatically maintained at a constant temperature by the hot oil heater.

CONTROL ROOM / PANEL

- ● A fully AutomaticworldclassSCADAbased computerizedcontrolpanel Unlimited jobs Mix DesignParameters

- ● High resolutionscreen and 19" LCD color graphic monito rwith CPU for live operation on screen

- ● Safety signal indicators, which indicates the time service & maintenance requirements on the plant.

- ● World-class AC Drive Invertor for cold bin feeder

- ● Centralized operation measuring for batch Kg/per cycle of with homogeneousmix of aggregate, bitumen & minerals

- ● Manualoperation control ability for test trial or for maintenance.

- ● Unlimited memory data for Mix Design Recipes on PLC & SCADA index list.

- ● Production data printout per trip with total batch details.(Aggregate,Bitumen & Filler)

- ● Datahistory saved on PLC (Date, Jobmix, Data)

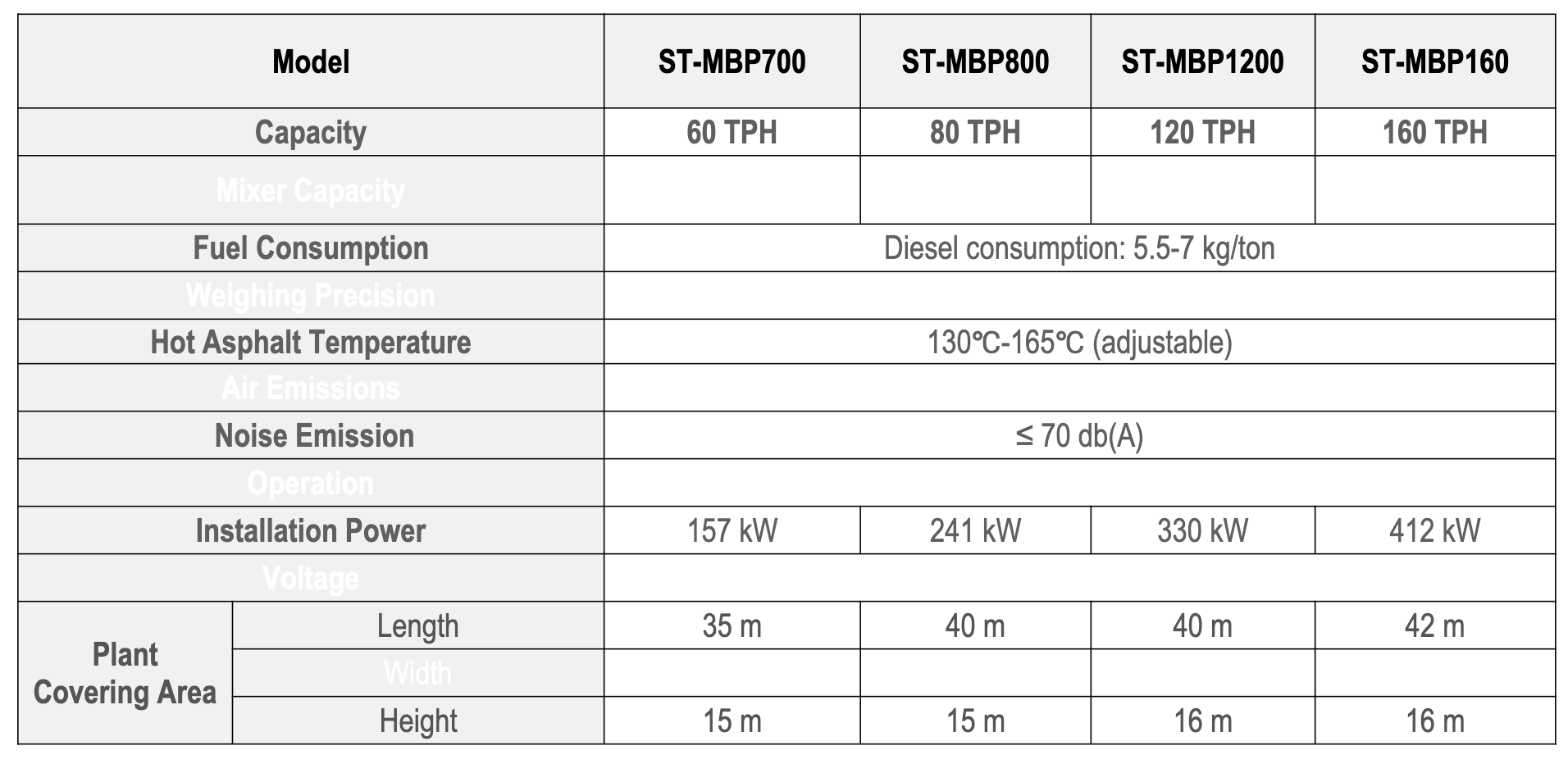

Technical Specification: